Top 5 Primary Aspects of Heavy Copper PCB Design in 2022

Printed circuit boards are found in different electronic and electrical components. These products are in reality thin boards prepared from fibreglass or laminate materials. Based upon the applications various kinds of boards are used. The base layer of a standard board is generally constructed from fibreglass. Under normal conditions, these layers perform well. At high temperatures, this material however does not perform effectively. As a result, they sustain heavy damages.

Various aspects that require consideration

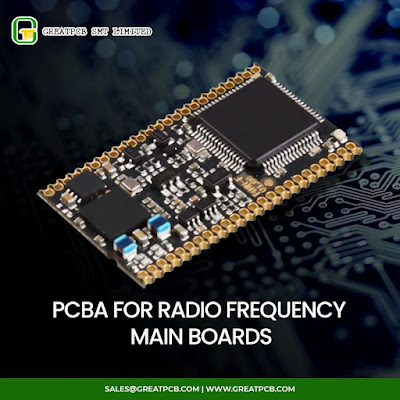

In the printed circuit board industry, the current trend is circuits made from copper. There is a relationship between heat rise and the flow of current. During the flowing of current through a trace localized heating occurs due to power loss. The cooling of traces occurs due to conduction and convection. Estimation of heat rise is essential for obtaining information about the safe transmission of current. Learn about the extensive use of heavy copper PCB through GreatPCB in electronic circuitry requiring high power.

1. Use of modern technology in different applications

Technology has advanced at a rapid pace. For high-end applications, heavy copper PCB is a great choice. With the development of society, the demand for these products has risen significantly. They are in substantial demand for a wide range of electronic industries. This technology can operate complex switches in those areas facing space constraints. They are used in the following applications generally:

· Torque controls

· Power line monitors

· Rail traction systems

· Overload relays

· HVAC systems

2. Maximum reliability

The motivating factors behind this technology are efficient thermal management and stable performance. The boards of modern times are constructed in such a manner to allow the passage of heavy currents. The process involves the generation of high heat. The optimal performance of the board takes place due to the efficient dissipation of heat. You may be unconvinced about the host of benefits that one can derive from electrical applications. In these situations, get in touch with an electrical specialist or a reputed manufacturer. Such companies are known for their supply of reliable components.

3. Going through the guidelines

In cases where controlled dielectric needs exist, the heavy boards will require this chemical element. To prevent the occurrence of short circuits space and trace width in heavy boards are increased to a significant extent. Upon request, reliable companies may satisfy customized needs. However, in these cases, the pricing structure is a bit higher. It is a prudent idea to send all the specifications and files you have to a reputed manufacturer for review and for getting a quote.

4. About their performance

Their performance is not affected by processing temperature. The elongation performance is the best. These products can even hold well during hot-melt welding procedures and do not show signs of brittleness when exposed to low temperatures. This chemical element develops a robust non-toxic layer even in the presence of a highly corrosive setup.

5. Unique features

These products have unique features. So they are appropriate for high-end applications. Some of the advantages are highlighted below:

· Thermal distribution

The copper-plated vias have powerful thermal resistance. They are in frequent use in sectors where high frequency and high speed are the need of the hour.

· Mechanical strength

These boards have incredible mechanical strength. They add to the robustness of the electrical system.

· Effective conductor

They are good conductors. So they play a vital role in the manufacturing of electronic devices. They assist in the joining of different boards together.

Act intelligently

Immerse yourself in extensive study to obtain information about companies that have gained a place of prominence in printed circuit board fabrication.

Thank you sharing for this great post.

ReplyDeletepcb board makers