Defining Printed Circuit Board Assembly - Greatpcb.com 2020

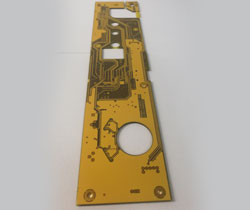

Printed circuit board assembly is the course of action that involves the placing of a host of electronic components to a circuit board. The objective is to build an entirely functional circuit assembly. In this procedure, there is the involvement of two construction types, and they are through hole and surface mount. Just like any other process, you will encounter merits and demerits along the way. From the perspective of space occupancy, the surface mount is beneficial. In contrast, vigor is incorporated in the elements which are likely to face considerable stress.

Gain insight

In modern times it

is tough to imagine life without the printed circuit boards. It would help if

you got in touch with a competent company known for its supply of boards, which

act as the base of various electronics types. Obtain contact details of PCB board assembly manufacturers through the

website of GREATPCB SMT LIMITED.

Focus

on core tasks

The assembly system

requires the utilization of a wide range of techniques for establishing the

connection of the electronic components. In cases involving substantial volume

fabrication, strong wave soldering is used due to their low melting pint. Get

quotes on PCB board assembly from GREATPCB SMT LIMITED experts online. The moment you

decide on outsourcing your manufacturing requirements, you will be able to

attain mental peace. Now you are aware that the crucial task of assembling will

be tackled efficiently by experts, and that will leave you with ample time to

take care of the sales target and think of ways of augmenting the marketing

network.

Economical

option

If you have been

thinking of creating the assembly unit on your own, then be prepared to part

with a considerable sum of money. You can overcome this hassle by contacting a

manufacturer involved in this line of work. A firm will be able to outsource

those expenses at ease and carry out operations smoothly. The manufacturing

company which you have in mind has a team of skilled people who will ensure

that you get superior quality products. In the finished products, the chances

of faults are cut down significantly. You will not even have to be concerned

about building a separate unit for quality control. These experts make sure

that the products adhere to the latest industrial standards.

Coping

of design errors

Before the actual

production occurs, the assemblers often use special software to perform the

task of assembling on the digital mode. The objective is to minimize the

chances of mistakes and cutting down on delays. The experts in this way can

tackle designing issues before the commencement of actual production. Incorrect

footprints can pave the way for delays in production. Automated operations call

for fewer employees. As a result, the assemblers can pass on these financial

savings to the consumers as lowered costs.

Sensible

call

It would be best if

you zeroed down upon a company for your printed circuit manufacturing needs

only after extensive research via online. You may seek recommendations from

your acquaintances in the industry. Rely on the feedback of clients for getting

a fair picture of the company.

Electronics manufacturing service Really I enjoy your site with effective and useful information. It is included very nice post with a lot of our resources.thanks for share. i enjoy this post.

ReplyDelete