An Intelligent Approach for Improving the Printed Circuit Board Assembly Process

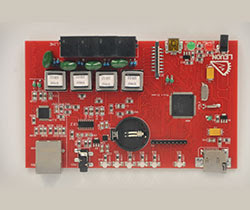

Printed

circuit board assembly includes several machines in their all over-processing.

The machines may be stencil printers, reflow ovens, and many other distinct

components that perform as a whole in the assembling process. Not only for

manufacturing purposes, but some mechanisms are also there to combat failures

in the circuits. Multiple parameters play a role in improving the assembly

process and optimize effective performance. The following are some of the

helpful and intelligent approaches to address the distinct challenges in the

path of improved functionality.

Smart manufacturing

The first

step of achieving the discussed goal in this work field is to find

a service provider that can come up with smart solutions to your needs. There

are many challenges in this field that requires overcoming. For achieving a

smart manufacturing approach, the companies need to focus on the management of

complexities, regulation, standardization, infrastructures, better training,

and resource management. It would

be best to connect to PCB assembly services suppliers, like the professional

company GreatPCB that efficiently serves

to yield quality outcomes in PCBA and its manufacturing.

- Data analytics

Big data analytics is a term that is being gradually coexisting with the PCBA management system for overall improvement. It is an efficient technique to analyze business strategies and insights as the complexities of the data have hugely expanded. The seven dimensions of big data that set the analyzing components' parameters are complex to understand but functions in the right direction. The PCB assembly services suppliers can modify the dataset members to formulate these in PCBs as per the industrial scenario. It is high time to adapt to these new-age methods.

- Experimental benefits

To apply

modern strategies, you need to select the critical parameters and experiment to

optimize the existing performance to achieve improvement. Formulating minimal

experiments in a segmented way is a highly promising approach that helps

measure the system and parameters. For example, trying the signal-to-noise ratio for measuring performance works greatly. The Taguchi method says that

considering multiple parameters is better as singular alteration cannot truly

benefit the allover performance. These experiments can work greatly under smart

manufacturing infrastructures where the investigation of critical PCBA

parameters can prove effective.

- Improved design

Improvement

in designing modules by incorporating a segmented approach can certainly work

in the right way. For this, the new and improved architectural designs have

three modules that help in achieving distinct functionalities. They are:

- Data collection module: For collecting necessary data PCBA process

and facilitate the data analysis procedure.

- Failure analysis module: The FAM plays a vital role in determining

the critical parameters via investigation of the NG types.

- Machine setting optimization module: The MSOM, specially designed module for

optimizing the process parameters that got through the failure analysis

module.

All of these

works simultaneously for obtaining a better processing performance of the PCBs.

- Consider these

A practical

approach to improve efficiency is the case studying of the feasibility of the

proposed architecture. To strengthen the process, the company possesses several

components like a lead-free reflow oven, buffering machine, automatic optical

inspection machine, in-circuit tester, and many more that help in the detection

procedures. Also, effective management methods to reduce the yielded loss are a

part of improvement.

Automation is

the key

On the final

note, something that requires immediate attention is the incorporation of

artificial intelligence. It can understand the data in a deeper way and play a

crucial role in decision-making that can eventually cut the production cost and

improve the quality of the PCBs. Use the subdomains of AI, such as machine

learning, data, and deep learning to manufacture better units.

Comments

Post a Comment